DPF Regeneration

The particulate filter, or DPF, is a very important element of the exhaust system of diesel engines. It is the only place through which exhaust gases pass while simultaneously trapping so-called particulates that are too large to pass through DPF filtration. They consist of ash and soot, which is gradually removed during the filter regeneration process while driving. Unfortunately, the DPF burning process during driving does not remove various types of ash. Therefore, over time, due to the gradual accumulation of ash, partial clogging of the filter or even formation of compacted mass in the central part of the filter occurs. Ash is non-combustible and cannot be processed by thermal methods, so it must be removed from the DPF filter during a specialized cleaning procedure. DPF filter regeneration involves disassembly of parts and proper cleaning of the structure of elements responsible for stopping ash and soot during the fuel combustion process. The accumulation of these substances is the main cause of DPF filter failure and a factor that greatly affects the limitation of exhaust flow, increased susceptibility to power loss and making it difficult for the engine to work continuously. Accumulation of soot and ash also affects the decrease in power of the drive unit, as well as a significant increase in fuel consumption.

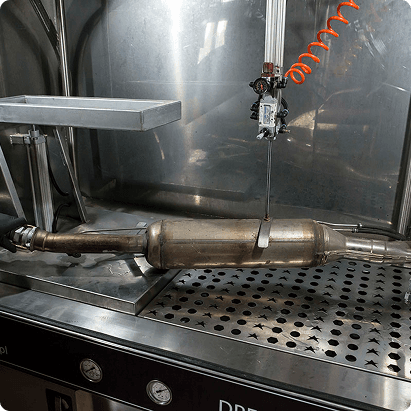

Professional and effective DPF filter regeneration consists primarily of assessing the actual condition of the filter and excluding mechanical damage to the internal ceramic insert using appropriate tools. In case of additional damage in the form of cracks in the ceramic insert of the catalyst or filter or mechanical interference with the DPF filter, regeneration will not be possible and it will be necessary to replace the filter with a new or used one with parameters corresponding to the damaged base filter. If no mechanical damage to the DPF filter is found, the system is mounted by us in a special chamber of the cleaning device. We carry out accurate measurements of the filter condition and the degree of contamination with particulates, so that it can be determined what cleaning procedures will be necessary to restore the filter to full usefulness.

The first stage of cleaning is dosing a specialized detergent, which is designed to dissolve accumulated engine oil and other contaminants that could hinder our work during filter regeneration. The detergent we use for pre-cleaning is completely safe for the environment and the structure of the entire filter. It does not affect its porosity or individual elements in any way. Additionally, it decomposes within 24 hours.

The DPF filter regeneration procedure is carried out in three cycles, independent of each other, to provide our customers with a comprehensive effective DPF regeneration service, which involves cleaning the interior of the DPF with water and air, which is supplied at the appropriate frequency under high pressure. The first cycle involves supplying the mixture back to the direction of exhaust flow. During the second cycle, air and water are supplied in accordance with the movement of exhaust flow, and the third cycle is a repetition of the first cycle and causes removal of accumulated impurities that could not be removed during the filter burning process while driving. In case of a heavily contaminated filter and lack of final effect, the procedure is repeated in its entirety.

The last stage of DPF filter regeneration is thorough drying of the filter with an air stream at a temperature of approx. 90°C, after which it is cooled. In order to verify the correctness of the entire procedure, we perform specialized measurements of the degree of contamination of the filter structure. In case of excellent results, we prepare a backpressure measurement printout, which is proof for the customer of the service performed according to expectations

Effective DPF Filter Regeneration

The DPF particulate filter is a very important element of the exhaust system of every vehicle with a diesel engine. Exhaust gases passing through the exhaust system are stopped by the DPF. Thanks to proper filtration, all pollutants remain on its walls. Some of them are burned by the filter while driving, but some remain and gradually deposit, causing partial or even complete clogging. To ensure smooth operation of your car and good technical condition of each DPF filter, it should undergo a regeneration process.

Learn more

Why Choose Us?

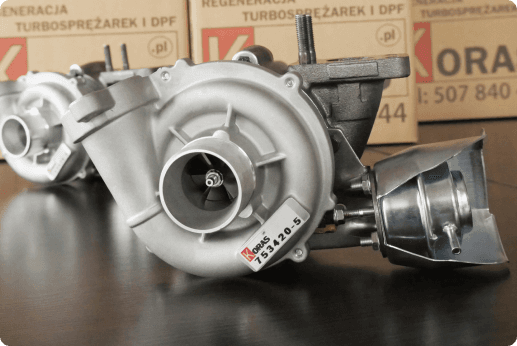

Free delivery when purchasing a new or remanufactured turbocharger

Delivery even within 24 hours

Highest quality parts with quality guarantee

Choose from thousands of parts

Our specialists will help you select parts, if you have questions or need support, call us